Last week Mark Reuss was interviewed by the Washington Post and clarified anticipated changes to the Ultium battery platform.

General Motors’ history with EVs is vast, beginning with the EV1, then Volt, Bolt, Cadillac ELR, each contributing to understanding customer needs, batteries, and vehicle integration. To reach General Motors’ goals of one million EVs sold by 2025 it will take massive changes to customer attitudes, charging infrastructure at home and commercially, an end to range anxiety (which already seems to have abated), and pricing that’s affordable. We think a great deal will depend, not on Bolt and Bolt EUV and comparable vehicles from Volkswagen, Nissan, Hyundai, and Kia, but on commercial trucks like GM’s new BrightDrop delivered to UPS, Federal Express, and Amazon. They will pave the way forward with battery (cell and pack) scale production.

According to Reuss, “So, we decided a couple years ago that we weren’t going to get into a large hybrid or plug-in hybrid play but rather go right to pure battery-electric vehicles based on all the learnings we’ve had and do it in a way that gets scale for people, both on the battery cost, the vehicle cost, but also build excitement into those vehicles for all the different tastes in customers that we have today.”

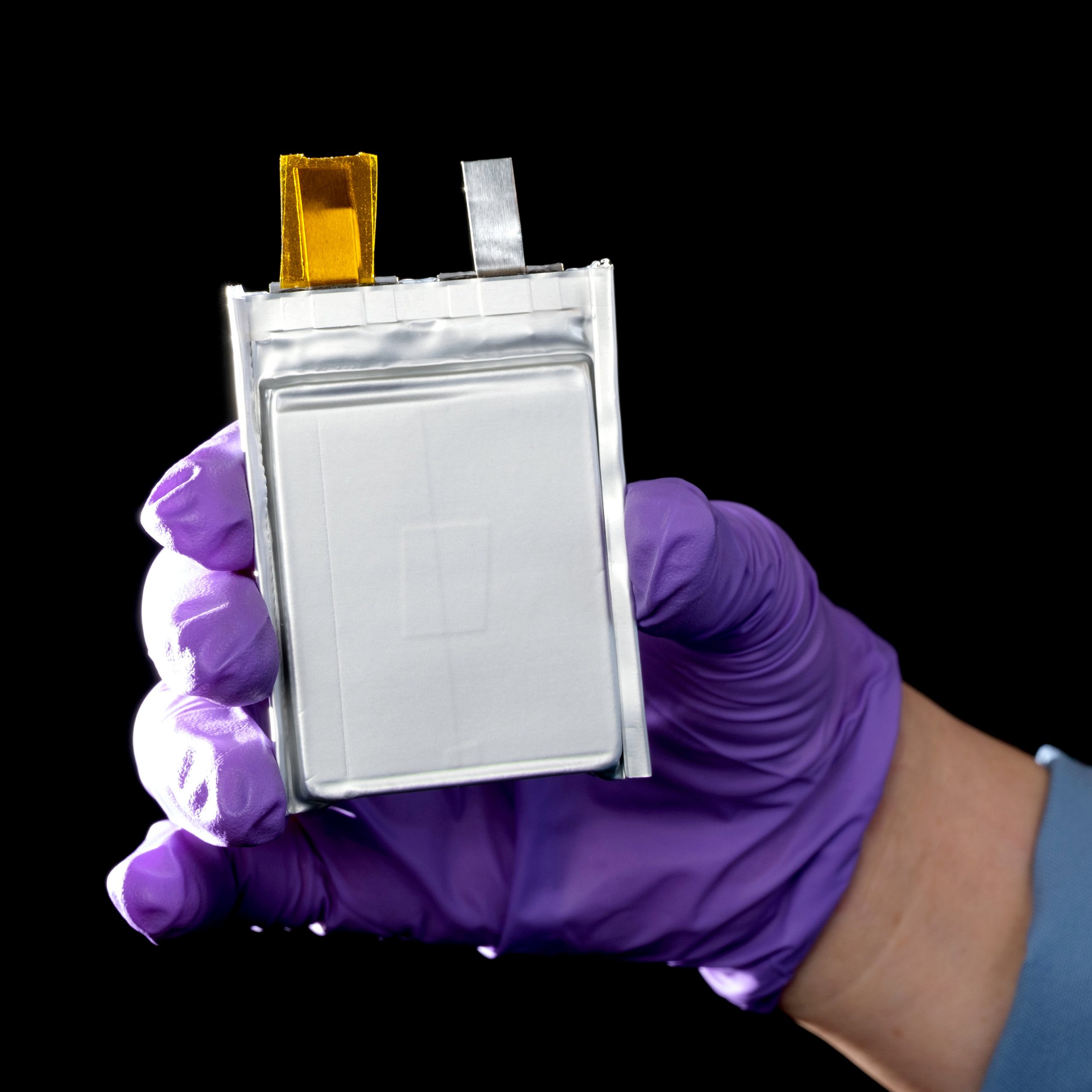

This brings us to the first Ultium battery, a pouch-type cell developed by GM and LG and to be built in a new battery production facility in Lordstown, Ohio. Note that the Ultium platform can use whatever type of battery cell—cylindrical, boxy prismatic, or pouch—is locally available. Reuss said that “the Bolt EUV will be the last battery pack off of our previous-gen chemistry. So, the next-gen with the Ultium platform starts with Hummer and then continues onward. So, everything past Hummer will be the Ultium platform…” and went on to outline General Motors’ joint development agreement with SolidEnergy Systems (SES), a developer of next-generation solid-state or “lithium metal batteries.”

The venture will build a prototype factory in Woburn, Massachusetts to build lithium metal batteries in 2023, a year after Ultium 1 appears in Hummer and Lyriq. When scale production of the new battery begins, the plan is for these new batteries to be backward compatible with all Ultium platforms.

Expectations are high, double the energy density (compared to current cells) and a 40-percent cost reduction. GM was an early investor in SES and now has 150,000 simulated miles of testing completed at the Warren, Michigan Tech Center. The expected range from a long-range battery pack could reach 500-600 miles in a Hummer, or deliver similar mileage, 250-260 in current the Bolt, at a lower cost and lighter weight.

“Affordability and range are two major barriers to mass EV adoption,” said Reuss. “With this next-generation Ultium chemistry, we believe we’re on the cusp of a once-in-a-generation improvement in energy density and cost. There’s even more room to improve in both categories, and we intend to innovate faster than any other company in this space.”