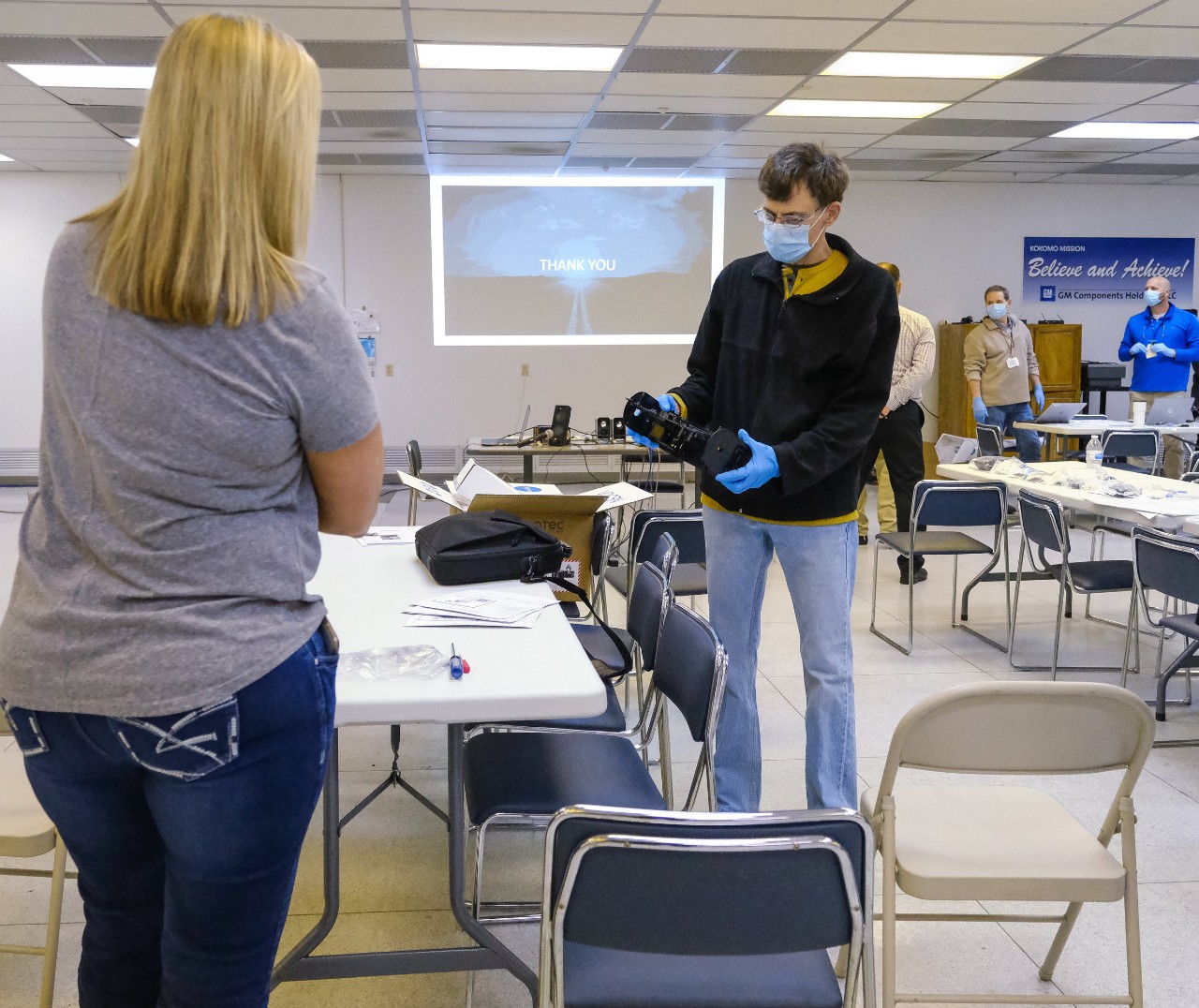

GM is taking steps to ensure worker safety as it builds ventilators.

GM’s steps include not just personal protective equipment but extensive pre-planning based on CDC guidelines to help distance workers from one another. “The men and women building these ventilators raised their hands to help save the lives of people suffering from COVID-19,” said Dr. Jeffery E. Hess, GM corporate medical director. “We will create a safe workplace using CDC guidelines and scientific data.”

That safe workplace has many new rules and guidelines for workers on the production line and those playing supporting roles. GM listed out some new ways the company will help to ensure worker safety. Here is a punch list:

-There will be a 30-minute interval between shifts to allow employees to clean their workstations when they arrive and again before they leave.

-There will be signage throughout the facility reminding team members to practice social distancing.

-Each workstation will be manned by one person, and each workstation will be spaced at least six feet apart.

-Cleaning crews will clean and sanitize common touch surfaces such as door handles, as well as common areas, at least three times per shift.

-Initial production will begin with one shift, with second and third shifts added soon thereafter.

-Each shift will enter and exit through a different door to minimize social contact.

One GM worker happy to put the new rules into practice is is UAW Local 292 member Debbie Hollis of Kokom. “I have family all across the country, so (COVID-19) has impacted everybody that I know and love,” Hollis said. “I’m grateful that I get a chance to do my part and be a part of something…we are modern-day Rosie the Riveters.”

Hollis is just one of the 1,000 men and women, including people who already work for GM and new hires from the Kokomo area who are working on the GM/Ventec ventilator project.

“As our nation struggles with the COVID-19 pandemic, volunteer UAW-GM members are doing a tremendous service for our country by volunteering to come to work to make ventilators in Kokomo,” said Terry Dittes, vice president, UAW-GM Department. “For that reason, the UAW has worked with GM to put in place stringent CDC health and safety protocols. Our goal is to make sure that each and every day, people return home to their families and communities safe and healthy. We applaud their courage in volunteering in our nation’s time of need, and we commend GM for working with the UAW to save lives across this country.”

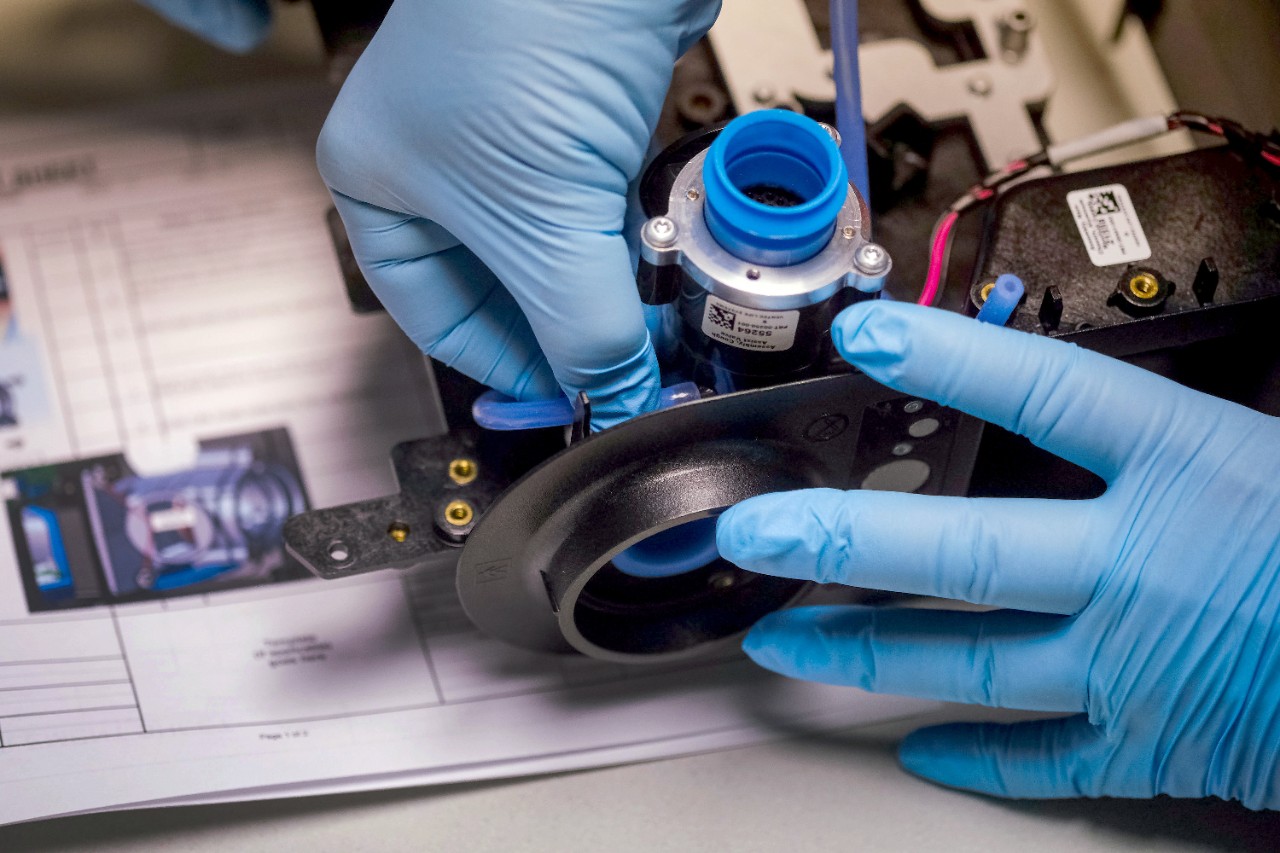

Mass production of the GM/Ventech ventilator begins in mid-April. Production will quickly scale up to 10,000 critical care ventilators or more per month. For more on this topic, please see our prior story.