The medical masks that GM is making for health care workers have earned an important certification.

The National Institute for Occupational Safety and Health, part of the Centers for Disease Control and Prevention, has certified that GM’s masks meet the requirements to be labeled “N95.” Only filtering facepiece respirators that filter out at least 95 percent of airborne particles during “worst case” testing using a “most-penetrating” sized particle is given a 95 rating.

The masks are part of the personal protection equipment healthcare workers need to protect themselves from infection when treating patients known to be or suspected to be COVID-19 positive.

Boston-area cancer center attending physician Hande Tuncer, M.D. told GM-trucks.com, “N95 masks are the hardest masks to come by.”

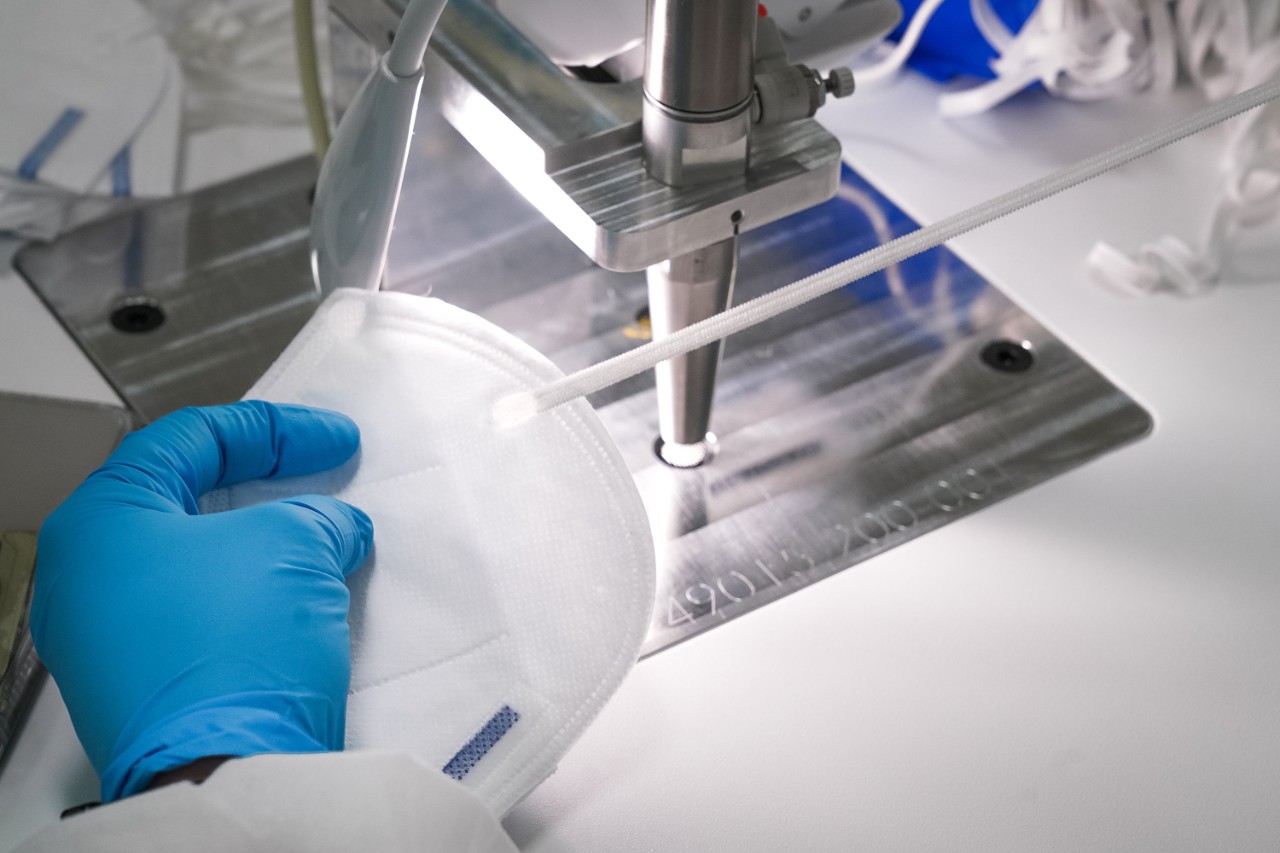

GM says that achieving an N95 rating required an entirely new manufacturing process with four separate stations to help create a tight seal around the user’s face:

Station 1: Four layers of fabric are sandwiched together, tack-welded in place and then cut into rectangular “blanks”

Station 2: Blanks are loaded into a template that welds the outer perimeter as well as the pocket for the wire nose piece

Station 3: The wire nose piece is inserted, the blank is folded horizontally and a sonic weld in the shape of a hockey stick is installed from the nose to chin

Station 4: The excess material is trimmed

To speed up the production of the N95 mask line, GM used sonic welders from the Brownstown Battery Assembly plant. The sonic welders were used in the Chevrolet Volt’s battery pack manufacturing process. For the N95 mask line, the welders were updated with new templates to create the weld patterns needed for respirators.

After the manufacturing is completed, the GM medical masks are subject to a quality check, are then cleaned, bagged and prepared for shipment.

GM says it will donate some of the N95 respirators to frontline workers. Since operations began just a few months ago, the Warren facility has delivered more than 4 million face masks and 230,000 face shields to frontline healthcare workers.

Images supplied by GM Media support.