Search the Community

Showing results for tags 'repair'.

-

I'm going to need to have the torque converter on my 2013 Silverado 2500 6.0 replaced & would like to have a price range in mind of what it should cost all said & done when I go to the shop so I don't get ripped off. I know rates & such vary depending on location (I'm in NJ) but I'm just looking for a round about price for this specific truck, maybe from someone who's been there & done that.. Any help would be appreciated. Thanks!

- 1 reply

-

- torque converter

- transmision

-

(and 3 more)

Tagged with:

-

Spent the weekend at a buddy's ranch, and the brake from a dirt bike dented my 2019 Silverado tailgate. I don't want to have to replace the entire tailgate, and I'm very unfamiliar with all the work that can be done now, so I'm wondering if paintless dent repair could fix this? Or if y'all think just the metal piece can be replaced without the entire tailgate needing to be swapped out? Thanks in advance!

-

2019 Silverado WT double cab, 4 wheel drive. 10,000 miles. well, what a crappy week. Got rear ended by a vehicle while I was sitting at a red light. 35-40mph impact to my rear hitch and bumper. Totally not my fault, the entire wreck was captured on my dash cam, and all costs listed below are being paid by the other person’s insurance company. And yes, I could see the guy typing on his cell phone with my rear dashcam moments before he slammed into me at full speed. Me and my 10-year-old daughter were in the truck. And yes, we’re both medically fine so I got two estimates today from two different auto body repair companies. Damages… (wait for it) Tailgate has to be replaced, right and left rear bed quarter panels have to be repaired, new bumper, new hitch, and the worst part… when the hitch went forward it sheared the holes in the frame rails where it attaches with bolts to the frame. Basically the 3/4” holes in the frame rail that the hitch bolts go through, became 3 inch holes after being stretched and torn from the impact. Both auto body shops said the entire frame has to be replaced with another OEM frame. They said that they normally could put it on a frame straightener and straighten the frame out, but the shearing in the middle could not be repaired to a point that they could guarantee that the tow rating would remain the same as the engineers at GM designed this frame for. Also, I asked about sectional frame repair. They both told me that GM does not authorize sectional frame repair on these trucks Therefore, a complete new frame is needed. The estimate average between the two body shops was around $12,000. Both shops said it would probably be in the shop for at least two months. The cost of two months rental for a full-size equivalent pick up truck is $99 a day. About $6000 bucks total. (could be more if not finished on time.) diminished value… Online calculators give a total diminished value estimate around $3000 due to the loss of trade-in value because of the now marred Carfax wreck history. (i’ll have to probably beg, plead, and pray to Jesus, to get that money out of the car insurance company. I’ve done it before in past wrecks, but I’ve also been told to, “kick rocks“ before.) and yes before anyone says it, I know I could “lawyer up” to get that money. But I really want to try to do this the right way first. There’s too much unknown of what will come next. Not saying I’m against lawyering up, but I’d really rather not. basically it’s a $21,000 minimum cost to the guy’s insurance company to repair this (when you add up everything mentioned above). keep in mind, my truck only has a actual wholesale value of around $28-$30,000. is it totaled??? Per my state law, if damages exceed 75% of wholesale value, the vehicle is a total loss. However, I don’t know if they are calculating the rental fees, and the diminished value cost in that math. Maybe it’s just the actual body shop work/parts cost. I’m not sure. I would imagine that they would include The total cost to the insurance company, since the Insurance company would not have to pay this if they just totaled the vehicle outright. so I find out in the next couple days what the insurance company is going to decide to do. I really hope they total it and I’ll tell you why… We all know that this truck was built in the GM assembly plant, to exact torque specs, clearances, etc. And a lot of that work was done by robots, calibrated tools, etc. I am sure “Billy Bob“ the autobody mechanic is not going to be as precise. (No offense to Billy Bob) If the vehicle is not totaled, and it is completely disassembled and reassembled by auto body mechanics, I will be selling it the day I get it back repaired. I refuse to drive around a “science experiment“. I feel like it will just be problem after problem from that point on. Forgive me if I’m being dramatic, but I really don’t even wanna take the chance. And God only knows how the hell that would affect my original factory warranty. I can see Chevrolet refusing to do anything with it from that point on. I’ll basically have to be going back to the body shop for any further problems. Then the body shop will blame Chevrolet, and vice versa. What a nightmare. and forgive me for calling the autobody mechanic “Billy Bob“. I have a lot of respect for these guys, and it’s truly an art that takes absolute talent to do. But I think we all know that I’m not wrong in assuming that this truck will not be built back to the same perfection that it came out of the GM plant with. I appreciate any thoughts or insights anyone on here might have. And just a reminder, any solid impact to your hitch will absolutely destroy your entire frame. The guy who hit me was only going about 35 to 40 mph. not sure what’s gonna happen from this point on, but I will be sure to update this post in the next few days If you are a religious type, any prayers are appreciated.

-

Proud owner of a new 2021 GMC 2500HD that needs some assistance with a problem concerning my driver's side mirror. That problem, was caused my me: The first time I backed the truck into my garage at night, I clipped the driver's mirror on the opening. I have 10' wide doors, so there is no excuse, so give ahead and give me the business! Hopefully you won't. Took a few photos and shared them with the dealer's body shop and I was told I have to replace the mirror at $1800. That parts were available, but nothing that would help me. Let me describe the damage: Looking at the front of the mirror (the side towards you with the mirrors), the lower fixed convex mirror cracked and fell off. The main mirror works fine. It can be remotely controlled and tilts downward when reversing, as I had it setup in settings. The mirror folds and extends with no problems. All the electronics work including the blind spot indicator, front LED white lights, the rear LED white lights and the amber markers. There is not a mark on the mirror housing. What cracked was the black plastic piece that holds the mirrors. The chrome surround housing that the black plastic snaps in to is untouched. The more I look at this mirror, the more I think I can fix it with parts from an identical mirror from a salvage yard. I can post a few photos here if you wish. I'd love to see an exploded parts view from GM, but I don't have that access. This truck has all the mirrors for surround vision, towing and whatever else you can think. If anyone reading this is a GM tech or body shop tech and might be able to give me a hand, I would really appreciate it. Thanks much, Mike

- 7 replies

-

- towing mirror

- hd surround

-

(and 1 more)

Tagged with:

-

How's it going folks! I have an 06 Sierra in which it seems I have a bad Body Control Module. I started it up this morning and was surprised to see my ABS, Airbag, Charging system light on. Also no power locks, windows radio etc. I initially thought it may be the ignition switch as I had similar issues in my 04 Duramax and that was the fix, but nope. But to get to the point, I plan on obtaining my BCM through a junkyard and to install and relearn myself. I am wondering if my odometer reading will change when I put in the new BCM. I have heard conflicting statements that the mileage is stored in the BCM or the Instrument Panel Cluster. I'm not really concerned with the mileage being higher on the new BCM as I plan on driving this truck to the ground, but I don't really care for committing a felony if its lower.

-

Hi everybody, I have an electrical issue with my Silverado 2008, I need the manual. Other members shared this some years ago but now isn't in dropbox. I hope someone could share me the repair manual again. https://www.dropbox.com/s/rflvemxjpqfc4h4/Gmc_Sierra_Service_Manual_Repair_Manual_Fsm_2007-2009_Download.zip?dl=0

-

Enjoy! Here's a copy of the 2007-2009 GM/GMC factory service manual for trucks. It covers trouble shooting and advice on what and how to repair/rebuild everything with torque specs. 4.3L engine to 6.6L trucks with everything form bumper to bumper... https://www.dropbox.com/s/rflvemxjpqfc4h4/Gmc_Sierra_Service_Manual_Repair_Manual_Fsm_2007-2009_Download.zip?dl=0

- 13 replies

-

- repair

- torque specs

-

(and 4 more)

Tagged with:

-

Hey there! I'm going to do a public service to the GM Truck people and make a guide on how to remove your front fenders from your Early 00's Silverado, Sierra, Yukon, Suburban, Yukon XL, and Tahoe. It's pretty straight forward, but this guide should be a help anyway. If you would prefer to watch an in-depth video with the same steps I'm showing here, please click this link --------> Fender Removal Video 1. Here are the tools you will need: 13 MM Socket 10 MM Socket 13 MM Wrench 10 MM Wrench Socket Wrench Socket Extensions Penetrating Oil or WD-40 Bungee Cord(s) Patience Let's first go over why I'm doing this, this truck was donated to me and my father as a project and this fender has a nasty rust hole straight through. So, we're hitting the Pick-N-Pull tomorrow to get a new fender. (Remove your wheel(s) before this guide) 2. Remove the hood hinge (13MM Bolt), or the hood itself. We had a way to support the side of the hood we were removing so we did not need to entirely remove the hood. If you do not have a way to support the hood, you will need to remove the whole thing. 3. Remove all the 13mm's along the fender you are wanting to remove 4. Remove wheel well splash cover by pulling the head of the little clips to free the liner, here is what the clips look like: 5. Soak 13 MM bolt where the fender and rocker panel meet with lube then try and break it loose. (These are exposed so it'll be rusty.) 6. Remove the 2 hidden 13 MM bolts in the door jam, use a long extension. 7. Unscrew Airbox and remove the hose, next remove your air filter and the top of the airbox. 8. Release bottom part of the airbox by using a screwdriver to push the little pins down which will pop the box out. 9. Remove the 3 10MM bolts holding the airbox support down. Remove any remaining clips. 10. Loosen coolant reservoir and secure to the side https://imgur.com/gallery/jO3RCUZ 11. Remove all remaining 13 mm and 10 mm bolts holding fender to chassis. 12. Remove headlight by pulling up on the metal bars, removing them. Next, pull the light and disconnect the connectors. 13. Remove grill clip from fender 14. Remove the last bolt holding the hood hinge to the fender with a wrench 15. Remove 13 MM bolt holding fender in the wheel well (inner bumper) 17. Wiggle fender upward and pull, it should easily come off of the truck. Ta-Da! Now you have tons of access to work or you're halfway done replacing your fender. I hope this helps! If you have trouble, please comment or refer to this video: Thanks!

-

Hey folks, I'm in dire need of a front bumper for my 06 Sierra 1500. There are a few rust holes (Nova Scotia winters ) preventing me from passing my provincial MVI. My question is if a similar generation 1500 Silverado front bumper will fit my Sierra, as a local scrapyard has a magnitude of Chevys but not any feasible Sierra candidates. I know it wouldn't look too pretty, but this truck is necessity over style. New is out of the question as shipping in NS is ridiculous, cheapest OEM ripoff came to over $600 for a $150 bumper. Any tips or advise would be greatly appreciated. Thanks guys, -Nick

-

Question fellas And ladies, I typically don't post on forums, but I'm at a poss currently. My truck is 2010 Silverado 4.8 and after driving it for 30 or so minutes the traction control/ stabitrax light comes on, the tachometer cuts off and the truck feels like it's jerking going forward, if I'm stopping or stopped the truck stalls and won't turn back on for Maybe an hour. I've replaced the fuel pump, crankshaft position sensor, engine temperature sensor, replaced the plugs and wires maybe a year ago, and I don't drive it much because I live close to work. Yesterday I had been driving it a little farther because I thought it was fixed, but as I was getting on the highway, the truck popped/ jerked, and the stabitrax/traction control off displayed and a couple of seconds later, the tachometer went to zero. I was able to get her home, but the truck kept jerking all the way home. I think the problem is unrelated, but my oil pressure has been getting lower as I drive it. Any help would be great, thanks.

-

Hey guys, new to this forum. Recently purchased one of the dream trucks of mine, 2014 Sierra Z71 4x4 5.3l. Which I was finally able to afford lol, bought from a local dealer with 88k miles. Prior to purchasing I test drove it, checked the history and maintenance records from GMC. All seemed well, purchased it and few days later while driving home on the highway cruising about 60-70mph, I began noticing a really loud sudden vibration that would come and go every few minutes (feels like it’s coming from underneath the truck not sure), lasting about 5 seconds. Even around 20-30mph I notice some shaking. Seems to be shifting fine, drives pretty smooth other than these vibrations that are coming and going. I just don’t know what it could be. I didn’t notice it during the test drive, just my luck, hoping for the best. Any opinions are greatly appreciated, I attached a video as well of the sound. 85CD798D-6EDF-4AD3-896A-02B1F45F48D7.MOV

- 7 replies

-

- driveshaft

- transmission

-

(and 4 more)

Tagged with:

-

Possible cause of DTC P0777 for a 6L80 transmission - especially after a re-build, upgrade, or maintenance of the valve body (a chapter from my upcoming book, "Learn from my mistakes!") Here's the context: 2007 GMC Yukon Denali 6L80 Transmission (Early, 1st Design, original equipment, no prior work or refurbishment actions taken on this transmission/valve body/TEHCM (TCM) - just trans fluid change and filter change) 195,000 miles (not bad, eh?) 6.2 Liter L92 engine (Original Equipment, no serious work has ever been needed, never rebuilt - just well maintained) Vehicle is - from an interior perspective - 95% 'new'. I've spent the last couple of years restoring it. I've spent time and money on everything from new carpets to a new dashboard, HVAC assembly (in-dash), new seats, new seat motors, new windshield, new everything, for the most part I've done all this work myself. I've built up quite a tool collection and quite a bit of knowledge I work in the world of IT (Digital Experience Strategy for large and medium-sized companies) Being in this field of IT means I work all day in a world of total ambiguity and chaos where nothing is ever cut and dry and the options, ideas, and risks are endless...as are the personalities I deal with. Working on my vehicle - along with vehicle's owned by friends and family aware of my growing skill-set - provides me a level of calm and relaxation I can't find elsewhere How This Story Originates: In the last 4 to 6 months, I've noticed the transmission exhibiting a moderate 'clunk' when - IMO - it is shifting down from 3rd gear to 2nd gear, or during any low-load, low-RPM upshift from 2nd to 3rd gear. This happens only when there is low RPM / low 'Load' on the engine...followed by a quick increase in requested 'load'. For context, a situation wherein it commonly happens is during a slow-down at a stop light and my intentions are to turn right. I.e., 'right on red' with a slow, cautious crawl for safety. Assume no cars / traffic to negotiate (for simplicity). I'd say I'd be going at about 10 to 15 miles per hour...perhaps as much as 20 to 25 miles per hour...from a pre-braking speed of ~30 to 40 mph. I would take my foot off the accelerator about 100 to 150 feet before the red light and apply light braking. Once I'm in a position to begin my right turn safely, I would take my foot from the brake and apply ~30% to 50% throttle on the accelerator. At this point wherein I engage the throttle, it seems as if the transmission doesn't know which gear to be in. While it only takes about a second, it eventually chooses 2nd gear but in the process it makes a noticeable 'clunk'. To mitigate this 'clunk' I usually try to feather the throttle up a little bit before I'm about to release the brake (i.e., 2 - footed driving). Slowly getting the RPM's up above 1,000 before starting my right turn and releasing the brake seems to negate the clunk. I've also noticed this clunk never really occurs until the transmission fluid temperature reaches about 110 (or above) Fahrenheit ( + /- 10 degrees). All other gear shifts in all other situations are rather comfortable and exhibit no observable issues. The transmission (nor the engine) never produces any DTC codes. Using a capable scan tool to reset the Trans Adapts and manually doing the Garage Shift procedure doesn't result in a 'fix'. Neither has anything else I've tried. I have not - to this day - ever tried doing a "Service Fast Learn". This is a procedure only incorporated into a few of the highly expensive scan tools such as the OE Tech2 and the Snap-On. My Autel Maxisys Elite definitely doesn't have this special function. One of these day's I'll have this procedure done by the Dealer or someone with a capable tool. Last weekend, I decided to install a Sonnax Zip Kit for the 6L80. My thought process was that the temperature increase of the trans fluid was a key indicator and gave me good direction. I was thinking pressure was being lost when the internal components of the valve body heated up to a certain point and expanded ever-so-slightly...we're talking a thousandth or so of a millimeter in various places throughout the valve body veins / assembly...but enough where some trans fluid pressure was being lost in key areas and causing the resulting clunk. Because the valves themselves were a different metal (and some of them a type of polymer / plastic) and probably not expanding like the valve body casing, I figured this was a good enough hypothesis to start working against. The Troubles Begin.... To make a long story shorter for you TLDR-er's, the Zip Kit is now installed and the shifting concerns seem alleviated. I'll give it another couple weeks to make a full conclusion, however. But the big story I wanted to share was about a mistake I made during the installation of the Zip Kit...but I imagine it could happen during any valve body refurbishment, upgrade, or maintenance. It has nothing to do with the Zip Kit itself. The Zip Kit was well manufactured and has fantastic instructions...with pictures too! The Zip Kit installation - plus a desire to inspect and clean all valves - simply gave me the opportunity to make the massive screw-up which occurred. So to help out fellow techs or DIY'ers who may experience this in the future, I have attached a summary pictorial explaining what I did and what it caused...along with the now-obvious solution. Initial Start-up and Test Post-Cleaning, Assembly, Refurbishment - aka, "The Crucible": What should have taken just about 3 hours to complete ended up taking 4 days. After putting everything back together the first time, I started the vehicle. I left it in Park for about five minutes. No unusual noises, no "Check Engine" lights. Normal oil pressure, normal slow rise in trans fluid temperature. Normal idle RPM's. I shifted from Park to Reverse and back to Park - allowing about 3 seconds between each move. This was an effort to flush air out of the veins/pump which may have accumulated during the overnight hours (I started this job in the evening but didn't re-install the valve body and other components until the next morning.) I then shifted from Park to Drive. I expected - as one usually does - to feel the torque and the car's desire to move forward. But no, there was no forward engagement whatsoever. I then shifted back to Park and let it sit for a minute. I shifted to Reverse - no reverse engagement. I left it in Reverse for 5 to 10 seconds thinking it will engage once the 'air is pushed out from the pump and valve body veins'...and that's when the Check Engine light came on. Silly me. I put it back in Park. I figured, let's try this again...maybe it was a solar flare or perhaps CNN is talking about Mueller again... Nope - same bad result - no forward, no reverse, not even the sound of it trying to engage. From Drive I was moving the shift lever back towards Park...and during that time I stopped briefly at Neutral. A faint squeal noise was observed from the transmission. Knowing that a squeal noise coming from a transmission is not SKOOKUM (h/t Ave on YouTube - one of my all-time favorites), I left it in Park and shut the engine off. Exhausted, bewildered, and full of self-doubt, I removed the valve body and TEHCM two more times. For anyone familiar with accessing the transmission valve body on a 2007 - 2013 Yukon (and perhaps 2014 and beyond), you know it's not easy. Each time, the catalytic converters need to be moved / dropped. This means the O2 sensors need to be removed, the front drive shaft needs to be undone and moved off to the side a bit, the front right wheel and wheel well cover need to be removed, etc. etc. ....in addition to draining the trans fluid oil and making a mess of your garage floor and yourself. I did this without a lift...only a jack and jack stands...making me ache and strain in ways I haven't felt in years. Note to DIY's...it takes the catalytic converters a bit more time than you think in order to cool down to a manageable level...ask me how I know. Each time I went over the instructions for the Zip Kit step-by-step to make sure I put the pieces where they were supposed to go. Each time I questioned most everything about how I put things back together - were the seals matching up correctly? Were the electronics / wires completely connected? Were there any green fuzzies on the main connector going from the outside of the trans and into the transmission case? Were there any cut or broken wires I didn't notice or failed to inspect? Each time I examined every piece that I had touched and questioned everything!...or so I thought. The struggle was REAL! Approximately 8 liters of new Dexron VI ATF - along with both hands, the right side of my jaw, and my lower back - were abused in the process of this event. The Cause: In short, during the re-assembly of valves which I had removed for cleaning, I put two of them in backwards. When they were first re-installed, they seemed to fit and it appeared how I re-installed them was exactly how I took them out. But I was incredibly wrong on both points. It wasn't until I noticed the ATSG manual's depiction of the valve body assembly diagrams - and comparing them to how I had re-installed my valves - that I finally realized the reasons for DTC's p0777 and p0700 suddenly appearing. For SEO, (but explained in the pictorial), I'll simply say that DTC p0777 is "Clutch Pressure Control (CPC) Solenoid 2, Stuck ON" and was the only result post-assembly and start-up. However in the end there was nothing wrong with solenoid 2 whatsoever. The TCM/ECU only threw that code because the situation matched the DTC p0777 trigger conditions. At that point I was really close to spending ~ $600 bucks on a new TEHCM...and that's when I noticed I had installed Clutch Select Valve 2 and Clutch Select Valve 3 backwards. THANK THE GOOD PEOPLE AT ATSG WHO MAKE GOOD TRANSMISSION MANUALS..SPECIFICALLY THE DIAGRAMS (if only they were in color, btw.) Now getting people to read carefully...a different story , of course. I couldn't find too much on DTC P0777, so I suppose it's rare. But if you ever come across this DTC or other "solenoid stuck", "solenoid failed" types of codes - and especially if you've just completed a refurbishing / cleaning / Zip-Kit installation on your valve body - take triple notice of how you reassembled and re-installed those valves....ALL OF THEM! Thanks for your time, Jeff Alpharetta, GA

-

Rotor and hub assembly removal/replacement 2015 silverado 1500 LT 4x4 Long time lurker, first time poster I was in the process of changing the brakes and rotors, which was going fine until I got around to the passenger front. I get the caliper bracket off and get the brakes out of the way. Then that’s when i did it, I snapped off the tip of a t-30 torx bit in the head of the brake rotor torx bolt. I’ve tried everything that I can thing of to get it out. Ive tried to drill a small 1/16” hole in the center of the broken bit to have an edge to work with. I’ve tried hand impact tools to just work around it and get the bolt out with no luck. I’ve watched a bunch of good videos, but had no luck so far. That’s bring me to a possible ‘solution,’ as I have to change out the hub assembly,Moog 515160, anyway. I’m think that I could just remove the spindle nut, and the hub hardware bolts and that should release both the rotor and hub as one piece? Thanks in advance for any thoughts, info, guidance! I’ll get some pics to add tomorrow in the daylight.

- 3 replies

-

- rotor

- hub assembly

- (and 6 more)

-

I found it from amazonLaunch CReader 3001,here shows $24.99 https://www.amazon.com/dp/B07CH4D68Q/Launch Launch X431 DIAGUN IV,here shows $549 https://www.amazon.com/dp/B072FHLYRY/ That price is big difference,how to choose it ?

- 7 replies

-

- auto

- code reader

-

(and 2 more)

Tagged with:

-

From the album: random

My paint job is horrifying. -

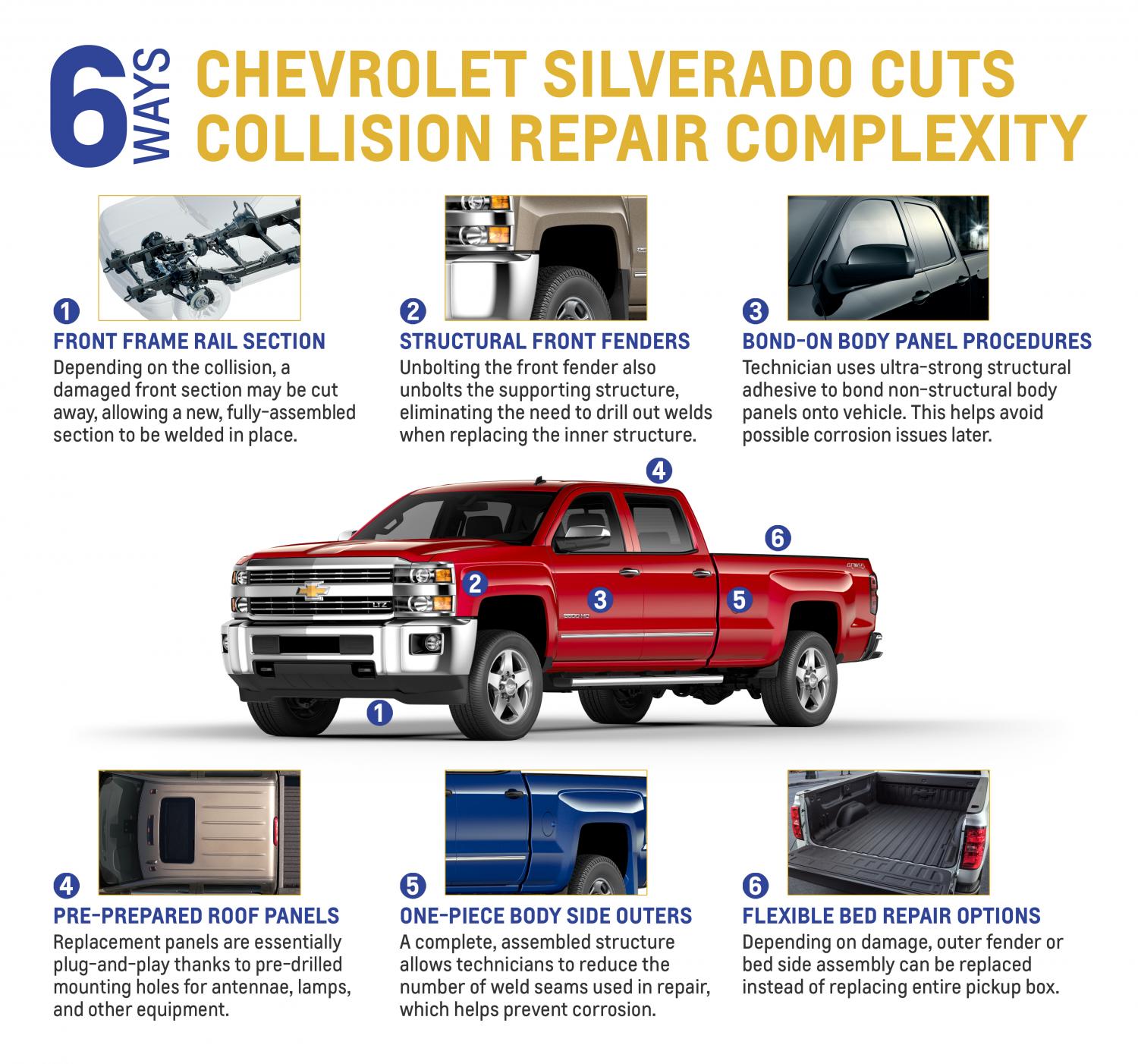

Today Chevrolet released an info-graphic that points out six of the ways that GM engineers designed the Silverado to be more cost effective to repair. Yes, this announcement is timed perfectly to scare Ford F-150 shoppers into thinking aluminum repairs will cost them time and money, but the truth is the Ford F-150 and many other commonplace vehicles have used aluminum body panels for a decade or more. Here are the six things Chevy thinks makes the Silverado easier to repair than competitors' trucks: Front Frame Rail Section Chevy says the leading section of its from frame rails may be removed or repaired making it easier to deal with frame damage. Structural Front Fenders Chevy designed the front fenders to unbolt in one larger piece, rather than an outer skin and inner supporting piece. This makes font end damage faster and simpler to work on. Bond-On Body Panel Procedures Rather than weld, some outer panels can be repaired using construction adhesives. Pre-prepared roof panels Chevy pre-drills holes for studs and accessories on its repair roof panels saving repair time. One-Piece Body Side Outers Chevy said in its announcement "If damage occurs to the outer panels of the cab, technicians can order a complete body side outer, shipped as a single, complete assembly, allowing technicians to cut out and replace only the damaged area instead of the entire assembly." Flexible Bed Repair Options Chevy designed its pickup beds so that owners can repair just the bed or bed box sides. Not all repairs require a full bed box replacement.